Güzeller Org. San. Bölg. Galvano

Teknik San. Sit. Cumhuriyet Cad. 2/32

P.K. 41400 Gebze / Kocaeli

Güzeller Org. San. Bölg. Galvano

Teknik San. Sit. Cumhuriyet Cad. 2/32

P.K. 41400 Gebze / Kocaeli

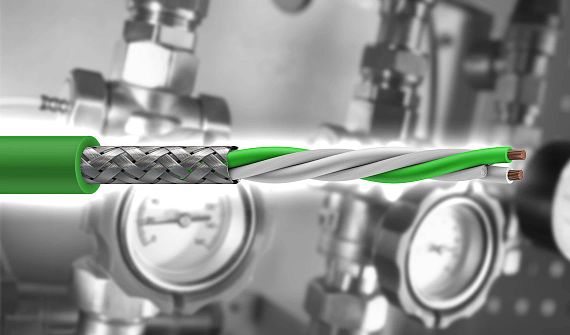

We developed the CFSPECIAL cable group for use in special applications. For special moving applications, only special cables can be used as they go beyond normal energy supply. However, this always means a minimum production quantity, which is usually unrealistic, especially for maintenance customers or very small applications. What is special about the CFSPECIAL family is that it is available as standard catalogue cables and can therefore be supplied quickly. This product range is slightly narrower, but we can expand it quickly if required. So, if you have trouble finding the right cable for your specific application, we would be pleased to hear from you directly.

A thermal compensation cable is the connection between a thermocouple and a measuring device. The thermal compensation cable must have the same materials as the thermocouple. The measurement would otherwise be distorted due to unwanted additional thermoelectric voltages.

CFFLAT: This cable has been specially developed for small installation spaces where large core cross sections are required. We use a flat cable design with a braided conductor in the core.

Cable for high-tensile-strength applications: Article Number CFSPECIAL.182 features our high-tensile-strength cable. The aramid braid built into the outer sheath allows this cable to withstand tensile forces of up to 15,000% higher than the norm.

Cables with the railway fire protection standard: Article Number CFSPECIAL.4xx features cables that have been classified according to DIN EN 45545-2, the railway fire protection standard. Cables have to meet special standards in order to protect passengers in rail vehicles. The main focus is flame resistance and low smoke fume development in the event of a fire. Since the requirements cannot be met with standard energy chain cables, it was necessary to develop a special solution. This section contains the result.

Seventh axis cables: A cable for supplying the entire robot when it is mounted on a so-called seventh axis. This axis that allows a robot to move along with the workpiece. The structure of the cable complies with the electrical specifications of the robot manufacturer.